JSAs, SWMS, SOPs and Risk Assessments in New Zealand – What’s the Difference?

Confusion around JSAs, SWMS, SOPs, SWPs, JSEAs and “Take 5s” is one of the most persistent and costly issues in New Zealand health and safety practice.

Many businesses treat these documents as interchangeable. Others collapse them into one form and hope that satisfies legal requirements. Unfortunately, under the Health and Safety at Work Act 2015 (HSWA), that approach creates real compliance gaps.

This article clarifies the correct role of each document, how they fit together under HSWA, and how to avoid the documentation mistakes that regularly fail under WorkSafe scrutiny.

Short Answer

JSAs, SWMS and SOPs are not the same.

Under HSWA 2015, businesses must manage risk so far as reasonably practicable. SOPs define how work is normally done, JSAs assess task-specific changes and risks on the day, and SWMS-style documents are administrative tools – not legal substitutes for risk assessment or higher-order controls.

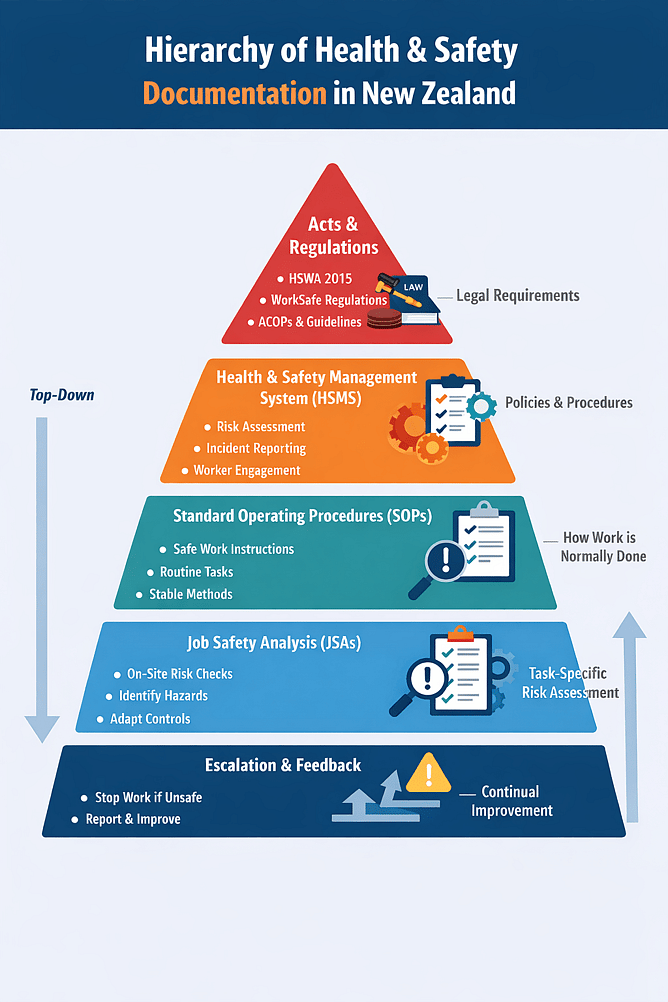

The Hierarchy of Health and Safety Documentation (HSWA-Aligned)

New Zealand health and safety documentation follows a top-down and bottom-up hierarchy.

At the top sit Acts, regulations, ACOPs and guidelines.

At the bottom sit task-level assessments completed by workers in real conditions.

Problems arise when businesses invert this hierarchy or expect task-level documents to carry legal weight they were never designed to hold.

Acts, Regulations and Codes – The Legal Foundation

At the highest level sit:

Health and Safety at Work Act 2015 (HSWA)

Health and Safety at Work Regulations

Approved Codes of Practice (ACOPs)

WorkSafe and industry guidance

Manufacturer instructions

These define what must be achieved, not how your paperwork should look.

Health and Safety Management Systems (HSMS)

A Health and Safety Management System explains how your business meets its legal duties.

This includes:

risk identification and assessment processes

incident reporting and investigation

consultation and worker engagement

monitoring, review and improvement

emergency and change management

Standards like ISO 45001 help structure this but do not replace HSWA obligations.

SOPs and SWMS – Planned, Routine Ways of Working

What Is a Standard Operating Procedure (SOP)?

An SOP describes how a task is normally done safely in your business.

SOPs:

are relatively stable

reflect legal and industry expectations

incorporate known hazards and controls

are informed by worker input

change when regulations, equipment or learning changes

They should not be rewritten daily.

What Is a SWMS in New Zealand?

In New Zealand, a Safe Work Method Statement (SWMS) is not a legal requirement.

Unlike Australia, HSWA does not mandate SWMS for high-risk construction work.

However, SWMS-style documents are commonly used as:

task method statements

administrative controls

evidence of planned work methods

Important:

A SWMS does not replace a risk assessment, nor does it satisfy HSWA on its own.

JSAs – Task-Specific Risk Assessment on the Day

What Is a Job Safety Analysis (JSA)?

A Job Safety Analysis (JSA) is a live, task-specific risk assessment completed:

before work starts

when conditions change

when work differs from the SOP

when new hazards emerge

JSAs are where real-world differences are captured.

What a JSA Is (and Is Not)

A JSA is:

a comparison between planned work and actual conditions

a mechanism to identify changed risks

a trigger for escalation if controls are inadequate

A JSA is not:

a replacement for SOPs

a generic form completed to “tick a box”

a legal shield if higher-order controls were ignored

How SOPs and JSAs Work Together (The Missing Link)

The most effective systems work like this:

SOP defines the normal, approved method

Worker reviews conditions on site

JSA identifies what is different today

Differences are controlled or escalated

Learnings feed back into SOPs

This creates continual improvement, not paperwork churn.

Why This Distinction Matters Under HSWA

HSWA requires PCBUs to:

eliminate or minimise risks so far as reasonably practicable

apply the hierarchy of controls

consult workers

manage change

verify controls work in practice

When businesses rely solely on JSAs or SWMS-style documents, WorkSafe regularly finds:

higher-order controls were never considered

risks were accepted rather than managed

documentation existed but systems failed

Common Documentation Mistakes That Fail Under Scrutiny

treating SWMS as a legal requirement

using generic JSAs for every site

updating JSAs instead of fixing SOPs

relying on administrative controls where elimination was possible

assuming experience equals competence

These are system failures, not paperwork issues.

Video: JSAs, SOPs and SWMS Explained Visually

This breakdown aligns with the explanation in our earlier video:

👉 “JSAs, JSEAs, SWMS, SOPs – What’s the Difference?”

The principles remain accurate – what has changed is the regulatory expectation around risk vs hazard and verification of controls under HSWA.

When a JSA Must Trigger Escalation

A JSA should stop work when:

residual risk remains high

controls differ materially from SOPs

weather or environment changes

equipment or access differs

workers cannot safely implement controls

If the risk cannot be reduced on site, it must be escalated – not worked around.

Final Clarification – One Sentence That Matters

SOPs define how work should normally be done.

JSAs assess what is different today.

Neither replaces the duty to eliminate or minimise risk so far as reasonably practicable.

Frequently Asked Questions

Are JSAs legally required in New Zealand?

No. JSAs are not mandated by HSWA, but they are a recognised method of task-specific risk assessment.

Is a SWMS required under HSWA?

No. SWMS are not legally required in New Zealand, but may be used as an administrative control.

Can a JSA replace a risk assessment?

No. A JSA is a form of task-level risk assessment but does not replace broader risk management duties.

Who should complete a JSA?

Workers performing the task, with input from supervisors and access to SOPs.

Can generic JSAs be used?

Only as a starting point. They must be adapted to site-specific conditions.

About the Author

Matt Jones is a HASANZ-registered health and safety consultant and the founder of Advanced Safety. He works with construction, infrastructure, manufacturing and service organisations across New Zealand to design practical, HSWA-aligned safety systems that stand up in the real world – not just on paper.